|

Database of Waste Management Technologies |

|

Case Study 10 - Waste to Energy (WtE)

| General Information | Photo Gallery | |

|---|---|---|

| Name: | Sheffield Energy Recovery Facility (ERF) |

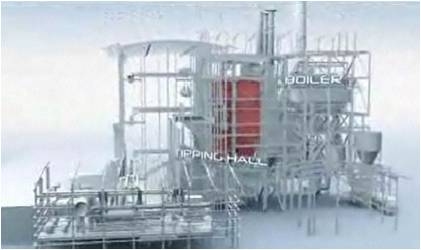

WtE Plant in Sheffield UK

View of the skeleton of Sheffield ERF |

| Owner: | Veolia (partnership with Sheffield City Council) | |

| Operator: | Veolia | |

| Technology: | WtE Incineration (combined heat power recovery) | |

| Designed Capacity: | 225,000 tpa | |

| Cost: | £68 m (project budget) | |

| Location: | Sheffield, UK | |

| Served Area: | Sheffield Municipality | |

| Commercial Start Up: | 2007 | |

| Contact Details | ||

| Address: | Veolia Environmental Services, Operational Service, Lumley Street, Sheffield S4 ZZJ, UK |

|

| Phone Number: | +44 0114 273 4567 | |

| Fax: | +44 0114 228 3551 | |

| Email: | Sheffieldenquiries@veolia.co.uk | |

| Website: | www.veoliaenvironmentalservices.co.uk | |

Short Description

The History

The city of Sheffield, along with the rest of the UK, has been under ever-increasing pressure to manage and dispose of its waste in a more environmentally sustainable and cost-effective manner.

Unlike most other large conurbations, Sheffield has a relatively low level of waste going to landfill. This is down to an innovative approach in the 1970s to integrate the waste incinerator with a network of pressurised hot water pipelines under the city to recover heat from household waste as well as producing electricity.

However, by 2000 it was clearly apparent that change was needed.

Economic growth meant that the level of waste arisings far exceeded the capacity of the plant.

With the EU Waste Incineration Directive (WID) looming in 2005, the City Council looked to external specialists to take matters forward under a 30-year Public Private Partnership (PPP), to manage the whole process from waste collection to management of the district energy network.

Veolia Environmental Services was awarded the integrated waste management contract in August 2001.

Various alternative technical and contractual combinations were explored to find the optimum solution to deliver the project. The result was an innovative combination of a turnkey contract with a Limited Liability Partnership, which subcontracted the works to CNIM (Constructions Industrielles de la Méditerranée S.A.) and Clugston Ltd. This provided the benefits of a single turnkey contract to the purchaser whilst limiting the risks for the two sub-contractors. Less than 5 years later, the new £68 million Energy Recovery Facility was operational.

Following investigation of alternative sites, it was agreed that the best location for the new facility would be alongside the existing plant.

The Facility

Sheffield ERF consists of one incineration line, capable of processing approximately 28 tons of refuse per hour, allowing for a nominal refuse throughput of 225,000 tons per year.

The waste is feed in the furnace and burned at over 850oC. The 50 m high x 20 m wide boiler superheats steam to 400 oC. This steam, at 45 bar pressure, is sent to the steam turbine which generates 19MW of electricity, enough to power 22,600 households, and a further 60 MW of thermal energy, which provides heat to 144 private and public buildings via 44 km of pipework. About 60% of the waste is recovered as heat and energy in Sheffield ERF.

Ash from the furnace is removed at a volume of 22% of the input volume. Bulky items and ferrous metals are removed and sent to a local recycling company for sale back into different markets. The remaining ash ends up at a close site where it is recycled 100%.

The flue gas goes to a dry reactor where lime and activated carbon are injected. The lime absorbs acids such as sulphur and chlorine while the activated carbon attracts dioxins and heavy metals. The gas is then passed through filters where these pollutants and dust are trapped and removed. These make up 3% of the input volume and are claimed to be the only elements that are not recycled or reused. Emissions from the plant are said to be 10-60% below the maximum allowable.

The Sheffield’s Carbon footprint is one of the lowest in the EU. Sheffield’s WtE plant saves 21.000 tn CO2/yr by providing heat and energy to local properties that otherwise would have used primary fuels. Furthermore, the plant is located in the center of Sheffield, in order to minimize transportation costs and CO2 emissions from vehicles.

Key Facts

| Treatment Capacity: | 219,976 tpa | (Data of the year 2009) |

|---|---|---|

| Input Material: | MSW | 219,976 tpa |

| Output Products: | Electricity | 115,624.95 MWh pa |

| Energy exported to Community | 97,292.4 MWh pa | |

| Metals recovered | 7,337.65 tpa | |

| Incinerator Bottom Ash | 47,628.31 tpa | |

| APC residues | 5,084.14 tpa |

Extra Information