|

Database of Waste Management Technologies |

|

AD 5: Complete Dry AD (Dry Fermentation)

Complete Dry AD, or Dry Fermentation is a relatively new anaerobic process, similar to anaerobic digestion, but more simple in construction. Unlike “classic” AD, dry fermentation does not require the adding of water to the organic waste treated, since it operates at c.50% dry matter content. The process takes place inside a simple, closed container and recirculated leachate is added to provide humidity. The different stages of degradation (i.e. hydrolysis, acid and methane formation) take place in the same digester.

A pretreatment of waste must take place in order to separate the organic fraction from the rest waste. The organic matter is inoculated with substrate that has already been fermented. It is then filled into the digester and fermented under airtight conditions. Continual inoculation with bacterial matter occurs through recirculation of produced liquid, which is sprayed over the organic matter in the digester. No stirring of the organic matter is necessary during the dry fermentation process, as it is in conventional AD systems. The process is operated in a batch manner.

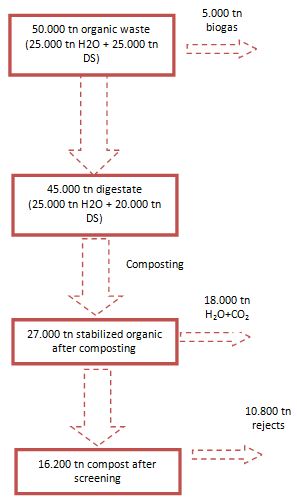

Products, like conventional AD, include biogas and digestate. Digestate however does not need to be treated to separate the solid and liquid phase. Normally, digestate is composted (matured) in covered windrows.

Process Mass Flow Diagram

Process Photo

Filling of a dry fermentation digester with the use of a front-end loader. The automated door ensures air tight conditions (absence of air) during operation (Technology of Bekon GmbH, photo from Bekon brochure, downloadable from www.bekon.eu)

Dry Fermentation digesters – technology TNS®-Loock (photo from www.helector-germany.de)

Process Operational Data

Area

An aerobic digestion facility must be accommodated in a sufficient space for fermenter and power unit installation. Some additional space for refining and storage is also necessary, while traffic and turning areas, a buffer zone for landscaping, wastewater treatment infrastructure and a small office must also be taken into account. According to data from various existing facilities (HYDER CONSULTING, 2007; ARI et al. 2008; RIS et al. 2005) land requirements range from 0.15 to 0.40 m2 per tonne input per year.

Energy

The energy requirements of dry fermentation are assumed to be supplied by the process itself with energy exploitation of biogas produced. The amount of produced biogas, which methane content is 55-65%, depends on the composition of feedstock. Comparatively little information is available on the amount of biogas produced by different feedstocks. The only pure research is from bench-scale studies carried for the USEPA, where the relative contributions of different materials to landfill gas generation (through anaerobic digestion) were measured. Results of this work, according to RIS et al. (2005), are presented in the following table.

| Material | Moisture (% wt) | Biogas Yield m3/kg of material feed* |

|---|---|---|

| Paper | ||

| Newspaper | 10 | 0.061 |

| Cardboard/Boxboard | 10 | 0.125 |

| Telephone Directories | 10 | 0.061 |

| Office paper | 10 | 0.178 |

| Mixed paper | 10 | 0.112 |

| Kitchen Waste | ||

| Food | 70 | 0.113 |

| Yard waste | ||

| Grass | 60 | 0.034 |

| Leaves | 0.023 | |

| Brush | 40 | 0.067 |

| Other organic | 0.101 |

According to data from various existing facilities the gas yields from the dry fermentation correspond to the specifications given by the Bavarian Institute for Agricultural Technology in Munich/Weihenstephan and vary from 100 m3 to 180 m3 per ton of feedstock. Less than 10 % of the power and 12% of heat produced in the co-generation unit is used in situ in order to cover the energy requirements of the facility.

Water

Unlike "classic" AD, dry fermentation does not require the adding of water to the organic waste treated, since it operates at c.50% dry matter content. Thus, water requirements of the process are minimized and they are estimated at 0.025 m3 per ton of organic feedstock.

Process Environmental Indices

Air Emissions

This process is enclosed and air emissions are unlikely to occur except during transfer to and from the digester. Anaerobic systems generate less emission than aerobic systems per kilogram of waste, since the principal gaseous emission (methane) is a desired product. However emissions related to the delivery of waste and mechanical treatment may cause emissions of odours and dust and the aerobic digestion of the digestate may cause a significant odour problem if not properly treated. Fugitive emissions of biogas are also possible from emergency vent valves and from poorly sealed water traps.

CO2 emitted from composting is not fossil-derived, and therefore, it is not considered as a greenhouse gas emission. According to IPPC BREF (European Commission, 2006a) fugitive emissions of CH4 are less than 1% of the total CH4 content of the biogas, ranging from 0 to 411 g per tonne of organic waste treated, while N2O emissions are assumed minimal.

The emissions generated by the combustion of the biogas are higher than the emissions generated during the biogas production process and they are presented in the following table (European Commission, 2006a).

| Pollutant | g/tonne |

|---|---|

| CO | 72.3 |

| NOx | 10-72.3 |

| SOx | 2.5-30 |

| VOC | 0.0023 |

| Dioxins/furans | (0.4 – 4) x 10-8 |

| Cd | 9.4 x 10-7 |

| Cr | 1.1 x 10-7 |

| Hg | 6.9 x 10-7 |

| Pb | 8.5 x 10-7 |

| Zn | 1.3 x 10-7 |

Wastewater

As no water is added in the process, leachate issues are minimized and the volume of generated wastewater is estimated around 0.05 m3 per ton of organic feedstock.

Residual

Residue consists of non-recyclable inerts which are not digestable, e.g., portion of glass, concrete, asphalt and ash, rock, textiles etc., which are removed during feedstock pre-process and compost refining processes. According to data from existing facilities residual is up to 0.22 tons per ton of feedstock.