|

Database of Waste Management Technologies |

|

Regenerative Thermal Oxidisers

Description

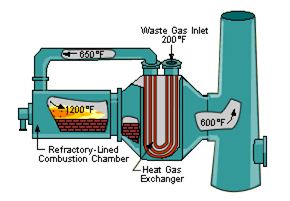

Regenerative thermal oxidizers (RTOs) and other types of thermal oxidation systems can be a highly effective and energy-efficient method of abating volatile organic compounds (VOCs) and other pollutants emitted by industrial plants. Thermal oxidizers are essentially incinerators that thermally or catalytically convert pollutant-laden emissions into CO2 and water vapour. The oxidation process typically achieves better than 99% destruction/removal efficiency levels for VOCs, hazardous air pollutants (HAPS) and odours. The thermal oxidation temperature is 750 to 900 degrees C.

Regenerative thermal oxidizers minimize fuel consumption by regenerating, or reusing, heat generated by the system. Prior to being exhausted to the atmosphere, the hot, purified air passes through a media bed to capture heat energy that will be used to pre-heat incoming air. RTOs can operate at thermal efficiencies of 85 - 99 %, reducing or eliminating the need to burn natural gas in the combustion chamber. Once the system is sufficiently heated, the natural gas burners can be turned off if enough flammable gas is present in the exhaust stream.

A regenerative catalytic oxidizer (RCO) is similar in design to an RTO, except that the ceramic heat exchange media closest to the combustion zone is coated or impregnated with precious metals that function as a catalyst. The metals enable oxidation at significantly lower temperatures (300oF to 550oC). A catalytic system requires the presence of the type of VOCs that will oxidize at these lower temperatures.

Achieved environmental benefits

RCOs have been reported to achieve:

- high VOC destruction rate (>99 %) - see table below

- reduced use of fossil fuel or waste fuel (high energy efficiency)

- at high VOC concentrations (>3 g TOC/Nm3), it is possible to operate in an autothermal zone. This means that minimum external energy is needed to be added to sustain the reaction.

| Characteristic | Value |

|---|---|

| Input flow ranger (Nm3) | 20000 - 80000 |

| Input VOC concetration (g/Nm3) | 2 - 4 with peaks of up to 10 |

| Output VOC concetration (mg/Nm3) | 15 - 50 |

| Efficiency (%) | >99% |

| Need for preliminary de-dusting | Yes |

| Risks | |

| Residues | No |

As for RTOs, the realised heat recovery rates vary between 90 and 98 % depending on the pollutant content of the exhaust gas. An additional supply of energy in this case is not necessary. With regards to the required values for the scrubbed gas, the systems currently available on the market differ in the technical method utilised for ensuring the lowest scrubber gas values. This is necessary because at the stream reversal point, remnants of the crude gas may pollute the scrubbed gas.

Systems optimised with respect to this problem can achieve scrubbed gas concentrations of less than 10 mg/Nm3.