|

Database of Waste Management Technologies |

|

AD 4: Wet AD followed by covered windrows composting

“Wet” AD technology

“Wet” AD systems used to treat municipal solid waste have been adapted from well established systems used to treat wastewater treatment plant biosolids. In essence, ‘wet’ AD systems process liquid materials (c.85% moisture). The digestion process takes place in sealed vertical tanks (digesters) that are usually continuously mixed to maximise contact between microbes and waste. Mixing can be achieved using mechanical stirring devices, or by recirculating biogas or waste through the digestion tank.

Transfer of material between several tanks is achieved through pumps. This type of wet system is better suited to feedstocks that are readily converted to liquid e.g. food wastes. In some ‘wet’ AD systems the waste preparation stage can be used to decontaminate mixed residual MSW by removing heavy and light contaminants through wet gravimetric separation.

AD technologies can be operated at moderate (mesophilic: 30 – 40°C) temperatures or high (thermophilic: 50 – 60°C) temperatures. ‘Wet’ AD processes can be operated at either temperature, but are most commonly mesophilic. In mesophilic systems, a pasteurisation unit is used to heat the material before or after digestion to achieve sanitisation.

AD processes can be single step processes where all the waste is placed into a single digestion stage/vessel, or a multiple step process using vessels to optimise different stages of the process. Multiple step processes often involve a separate hydrolysis stage, which can be aerobic or anaerobic, to breakdown complex organic material into soluble compounds. This is followed by a high-rate biogas production stage.

It is common in wet AD systems to operate as a “two-step” process utilising two reactors. In the first reactor hydrolysis takes place and in the second reactor methanogenesis takes place.

Biogas produced during anaerobic digestion is primarily composed of methane (typically ranging between 50 – 75%) and carbon dioxide, as well as smaller quantities of other gases including hydrogen sulphide. Biogas is also water saturated (100% humidity).

The amount of biogas produced using AD will vary depending on the process design, such as retention times and operation temperature, and the volatile solids (organic matter) content of the feedstock, i.e. the composition of the waste inputs.

Biogas is stored in large vessels prior to its use on or off site. Biogas can be used in a number of ways. It can be used as a natural gas substitute (distributed into the natural gas supply) or converted into fuel for use in vehicles. More commonly it is used to fuel boilers to produce heat (hot water and steam), or to fuel generators in combined heat and power (CHP) applications to generate electricity, as well as heat.

Biogas electricity production per tonne of waste can range from 75 to 225 kWh, varying according to the feedstock composition, biogas production rates and electrical generation equipment. Generating electricity from biogas is considered ‘renewable energy’ and benefits from support under the Renewables Directive.

In most simple energy production applications, only a little biogas pretreatment is required. Biogas used in a boiler requires minimal treatment and compression, as boilers are much less sensitive to hydrogen sulphide and moisture levels, and can operate at a much lower input gas pressure.

Where biogas is used for onsite electricity generation, a generator similar to that used in landfill gas applications can be used, as these generators are designed to combust moist gas containing some hydrogen sulphide. Gas compression equipment may be required to boost the gas pressure to the level required by the generator.

Some electricity is used by the AD plant, but excess electricity produced (typically ~75%) can be sold and exported via the local electricity distribution network. Excess heat can also be used locally in a district heating scheme, if there is an available user.

For high specification applications (e.g. vehicle fuel, natural gas substitute), or when using more sophisticated electricity generation equipment (e.g. turbines), biogas will require more pre-treatment to upgrade its quality. This includes the removal of hydrogen sulphide (a corrosive gas); moisture removal; pressurization to boost gas pressure; and removing carbon dioxide to increase the calorific value of the biogas. However, the cost of the equipment required to upgrade biogas can be prohibitive.

Organic matter leaving the digester forms a sludge-like material due to the high moisture content of the waste material entering the process and the breakdown of solids during digestion. The material produced is kept in a storage tank and can be mechanically pressed into its solids (digestate) and liquid (liquor) fractions.

The dewatered digestate may be used directly on land as a soil amendment provided it meets appropriate regulatory standards, or aerobically treated to produce a compost (if from source segregated material) or a compost-like output (if from mechanically separated material).

Some liquor may be recycled in the AD process to wet incoming waste; used directly on land as a liquid fertilizer due to its valuable nitrogen content (provided it meets appropriate regulatory criteria); or used to maintain moisture during the aerobic treatment of the digestate. Alternatively, if no other route is available, the liquor may be treated and discharged in accordance with permit requirements.

AD 4: Wet AD followed by covered windrows composting

This system incorporates Dry AD as described above, while the produced solid fraction (dewatered digestate) undergoes a further stabilisation step (composting). The composting system uses the “covered windrows” composting process (Composting 2). It should be noted that in this case, shredding in not a necessary preparation step, prior to composting.

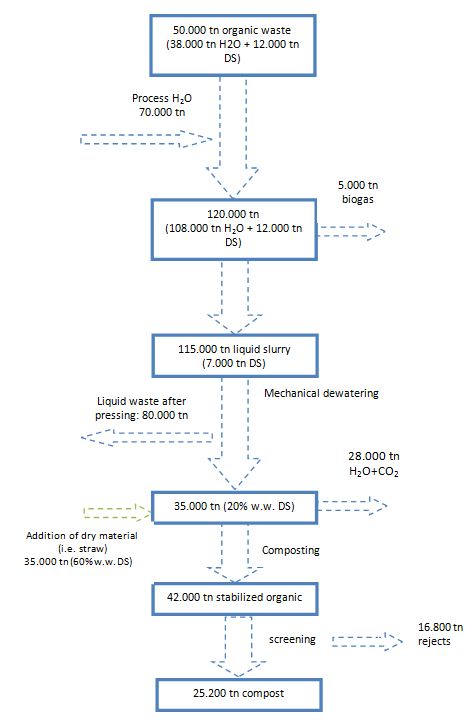

Process Mass Flow Diagram

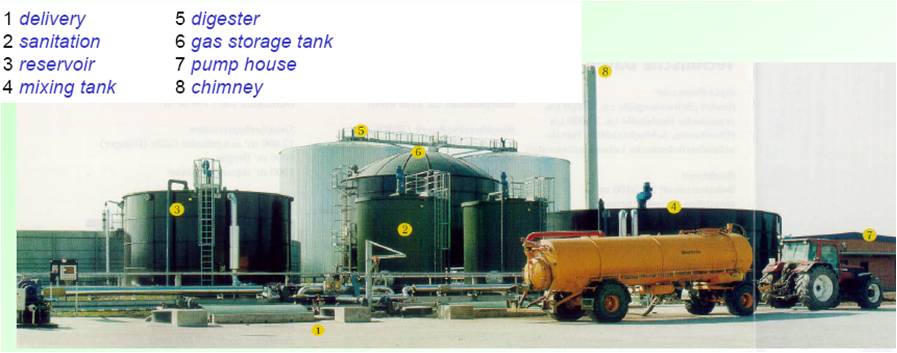

Process Photo

Process Operational Data

Area

An aerobic digestion facility must be accommodated in a sufficient space for digester and power unit installation. Some additional space for refining and storage is also necessary, while traffic and turning areas, a buffer zone for landscaping, wastewater treatment infrastructure and a small office must also be taken into account. According to data from various existing facilities (RIS et al. 2005) land requirements range from 0.10 to 0.25 m2 per tonne of organic input per year.

Energy

Unlike composting plant, AD facilities can potentially utilise some of the energy generated within the process to meet their requirements. According to data from various existing facilities (RIS et al. 2005) electricity consumption of facilities ranges from 85 kWh to 100 kWh per tonne of organic waste feedstock, while thermal energy requirements ranges from 15 kWh to 55 kWh per tonne of organic waste feedstock.

These energy requirements are supplied by the AD process itself with energy exploitation of biogas produced. The amount of produced biogas, which methane content is 55-65%, depends on the composition of feedstock. Comparatively little information is available on the amount of biogas produced by different feedstocks in an anaerobic digester. The only pure research is from bench-scale studies carried for the USEPA, where the relative contributions of different materials to landfill gas generation (through anaerobic digestion) were measured. Results of this work, according to RIS et al. (2005), are presented in the following table.

| Material | Moisture (% wt) | Biogas Yield m3/kg of material feed* |

|---|---|---|

| Paper | ||

| Newspaper | 10 | 0.061 |

| Cardboard/Boxboard | 10 | 0.125 |

| Telephone Directories | 10 | 0.061 |

| Office paper | 10 | 0.178 |

| Mixed paper | 10 | 0.112 |

| Kitchen Waste | ||

| Food | 70 | 0.113 |

| Yard waste | ||

| Grass | 60 | 0.034 |

| Leaves | 0.023 | |

| Brush | 40 | 0.067 |

| Other organic | 0.101 |

According to data from various existing facilities (RIS et al. 2005) biogas production ranges from 40 m3 to 120 m3 per ton of feedstock, with the lower values being characteristics of systems with shorter retention time.

Water

The amount of water added in the digester in wet systems is up to two times greater than in "dry" systems (HYDER CONSULTING, 2007). According to data from various existing facilities (RIS et al. 2005) is up to 200 kg per ton of input to digester.

Process Environmental Indices

Air Emissions

This process is enclosed and air emissions are unlikely to occur except during transfer to and from the digester. Anaerobic systems generate less emission than aerobic systems per kilogram of waste, since the principal gaseous emission (methane) is a desired product. However emissions related to the delivery of waste and mechanical treatment may cause emissions of odours and dust and the aerobic digestion of the digestate may cause a significant odour problem if not properly treated. Fugitive emissions of biogas are also possible from emergency vent valves and from poorly sealed water traps.

CO2 emitted from composting is not fossil-derived, and therefore, it is not considered as a greenhouse gas emission. According to IPPC BREF (European Commission, 2006a) fugitive emissions of CH4 are less than 1% of the total CH4 content of the biogas, ranging from 0 to 411 g per tonne of organic waste treated, while N2O emissions are assumed minimal.

The emissions generated by the combustion of the biogas are higher than the emissions generated during the biogas production process and they are presented in the following table (European Commission, 2006a).

| Pollutant | g/tonne |

|---|---|

| CO | 72.3 |

| NOx | 10-72.3 |

| SOx | 2.5-30 |

| VOC | 0.0023 |

| Dioxins/furans | (0.4 – 4) x 10-8 |

| Cd | 9.4 x 10-7 |

| Cr | 1.1 x 10-7 |

| Hg | 6.9 x 10-7 |

| Pb | 8.5 x 10-7 |

| Zn | 1.3 x 10-7 |

Wastewater

The amount of water added in the digester in wet systems is up to two times greater than in "dry" systems (HYDER CONSULTING, 2007) resulting in increased volumes of generated wastewater. According to data from existing facilities the volume of generated wastewater is up to 1.6 tn per tonne of organic waste feedstock.

Residual

Residue consists of non-recyclable inerts which are not digestable, e.g., portion of glass, concrete, asphalt and ash, rock, textiles etc., which are removing during feedstock pre-process and compost refining processes. According to data from existing facilities residual is up to 0.35 tons per ton of feedstock.